Managing pressure

Manage the pressure at your knapsack sprayer's nozzle to get best drop size for the best results. Learn how pressure causes drop size and which equipment will help.

Pressure and drop sizes

add

remove

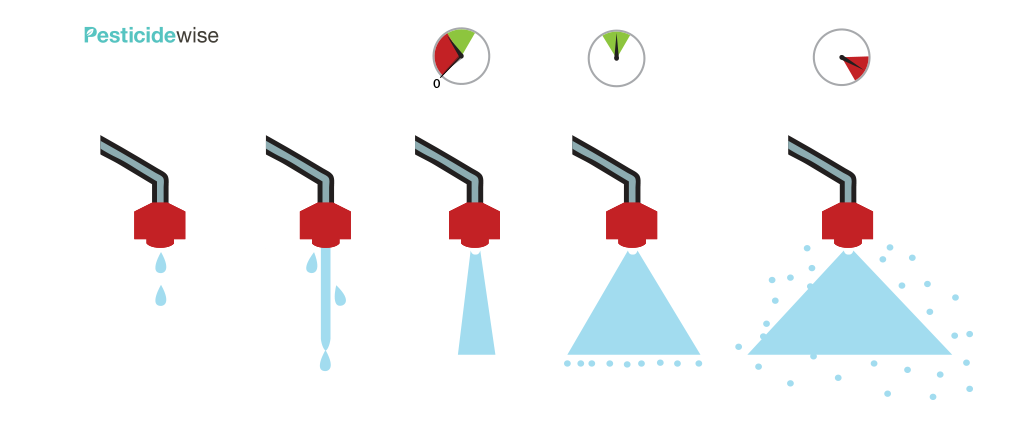

The pressure at the knapsack sprayer's nozzle must be right so that the right amount of spray drops are emitted in the right spray pattern and the spray drops land and remain on the target surface in the right spread of drops.

As pressure increases, drop size reduces.

- If there is no pressure at the nozzle, then no liquid or only one or two drips will be sprayed.

- If there is a little pressure, there may be a thread of liquid and a few spray drops.

- If more pressure is applied, a sheet of liquid will form at the nozzle to produce a narrow swath.

- The right amount of pressure will spray in the right pattern to form a swath of the right width when it lands.

- If the pressure is too high, the number of small drops increases.

The wrong pressure will mean that the pesticide does not give the best results.

- If the pressure is too low, the number and spread of drops and the pesticide dose will be too low to control the pest.

- The right pressure will apply the right number, size and spread of drops and the right pesticide dose.

- Too high a pressure will apply too many drops and too high a pesticide dose. The risk of drift, operator exposure and equipment damage will also increase.

Use the right pressure to get the right result.

Knapsack sprayer valves

add

remove

Better knapsack sprayers have valves to help you manage pressure.

- If there is not enough pressure, the nozzle valve will remain closed.

- At the correct range of pressures, the nozzle valve will open.

- If the pressure is too high, the pressure relief valve in the pump chamber will open. This lets the spray mix back into the tank and stops the spray going through the hose to the nozzle.

Pressure regulators

add

remove

Pressure regulators control the pressure at the upper and lower limits.

- At low pressure, the gap is closed and spray mix cannot reach the nozzle.

- At the right range of pressures, the force pushes the pin down to allow liquid to pass through the gap and into the nozzle.

- At high pressure the pin moves further down the valve: the wider end of the pin makes the gap smaller and lowers the flow of spray mix at the nozzle to the right level.

Choose a pressure regulator (e.g. Cooper Peglar's pressure regulator, Gate's CFValveand Jacto's EcoValve [289 kb pdf]) that sprays at the pressure you will need. Some spray at 1, 1.45, 2 or 3 bars. Lower pressures are useful with deflector nozzles and higher pressures for hollow cone nozzles.

Pressure gauges

add

remove

Choose a gauge with a scale that it is marked at useful intervals and shows upper and lower limits. For example, this pressure gauge has a:

- green area to show the safe pressures at which to spray

- red area to show when the spray pressure is too high.

Most gauges show the pressure of the spray liquid in bars.

Use the gauge to help you maintain the pressure advised by the nozzle maker and used to calibrate your knapsack sprayer. Take care that the pressure does not vary as you tire. Check your gauge often.

Checking your pressure gauge before spraying pesticides