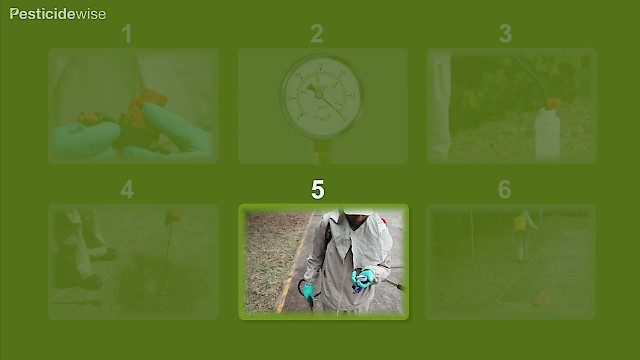

Step 5 of 6 - calibrating your knapsack sprayer for pesticide dose and spray mix/water volume

Description

add

remove

Description

This video will demonstrate maintaining spraying speed, the nozzle distance and knapsack sprayer pressure. Click the play button to view the video now or to view the video off-line, click the link from the 'download' tab.

Script

add

remove

Script